Fibrous Casing

What is the Fibrous casing?

STS Fibrous casing is a cellulose-based casing strengthened with natural long-fibered abaca paper, sometimes called manila hemp fiber, which combines exceptionally high tensile strength with consistent extrusion properties in a form that renders it ideally suited for sausage casings. Due to its strength and dimensional stability, fibrous casing is traditionally seen as one of the most versatile and comprehensive packaging materials.

Product options.

Tailor-Made Products

The STS Fibrous casing can be tailor-made to fit any application and production process. First of all, the right paper needs to be selected in terms of size, strength and extension properties. Secondly, the cellulose, or “viscose,” which is the technical name given to the soluble derivative of naturally occurring cellulose, is coated in a single or double layer and to the extent that’s required by the application and sausage process.

This latter form of cellulose is derived from the highest grades of purpose-grown pine trees. Once regenerated upon its abaca fibrous matrix, a variety of subsequent special treatments creates a casing to suit the most complex demands of the meat processor.

STS’s Fibrous casing offers the world’s widest choice of possibilities of tailoring to the specific needs of the meat producer or food packager. From this experience, we’ve developed a range of fibrous casings in over 80 different calibers and some 20 standard and variable non-standard colors to suit all applications, for both automatic and manual operations.

Adhesion levels

The basic fibrous casing, as previously described, is treated in a plasticization stage that involves multiple passes prior to drying, depending on the intended use. This ensures that the adhesion level of the casing is perfect for each application and production process. The casing can be sold as regular or treated with a meatcling and easy-peel coating and impregnation. Also, the adhesion levels and properties can be tailored to any application and process conditions. Improved meatcling is obtained by applying a substance that acts as a binding agent between the fibrous material of the casing and the proteins in the meat. Whenever easy-peel properties are required, the internal surface of the casing is treated with a release agent.

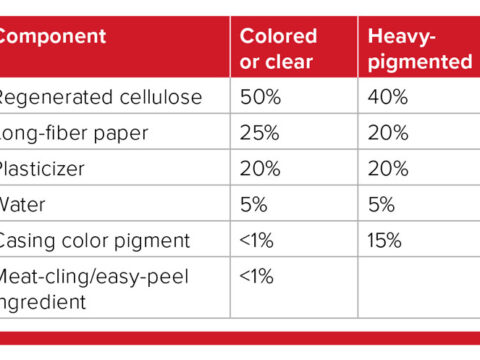

Fibrous casing composition

The average fibrous casing, regardless of its type and size, has the following chemical composition:

Strength and stretchability

Many of the properties of a fibrous casing derive from the use of long-fiber paper in its construction. In order to activate these excellent properties, the casing has to be moisturized. A dry casing has strength but no elasticity. By effective moisturizing methods–i.e., pre-soaking in connection with customizing or soaking immediately before use in the sausage factory–the casing is given the right combination of strength and stretch in order to ensure trouble-free sausage processing operations. STS can also offer the Ready-to-Use (RTU) pre-moisturized casing options that make it possible to use shirred strands straight out of the box while eliminating the risk of contamination from soaking water.

The right permeability

Fibrous casing is permeable to gases. This property plays a crucial role in the process where smoking, maturing and drying are required. By controlling the permeability levels of both water and gases, the casing will dry and shrink in a uniform way and allow the proper smoke transmission while maintaining caliber stability, thus ensuring very high yields.

Hard stuffing and high-speed peeling with Fibrous Xtreme.

Xtreme is a patented multilayer fibrous casing with an adhesion promoter on the inside layer and a moisture retention aid on the outside layer making hard stuffing and peeling possible. It’s designed to tolerate extreme conditions in dry sausage production with in-house peeling and slicing.

Xtreme Conditions

The STS Fibrous truly unique casing for the most extreme conditions and manufacturing processes, Xtreme makes it possible to push the limits for production and with perfectly modified adhesion and release properties, to reach the highest yields at all steps of the sausage making process. The strength of the casing not only makes it possible to stuff at the highest speeds; it also allows for perfect caliber stability and maximized sausage length.

Controlling both meat-cling and peel

What you end up with is a product that has all the advantages of good meat adhesion. However, with adhesion control modified and tailor-made to fit your process, it’s still possible to reach perfect peeling conditions. We can offer two standard adhesion levels (XM HPU and XM HPM) with the ability to tailor-make according to your specific process requirements.

Essentially, this casing allows for controlled meat-cling levels at the initial steps of the sausage production process. However, when also adding a fixed-rate peel injection, you’ll achieve improved peeling and moisture retention by the time the sausages leave the rack

Total adhesion control.

Adhesion control is a key element in a tailor-made fibrous casing. It’s also one of the keys elements when taking the full control of the sausage-making process and in peeling operations. STS masters both injection and bubble techniques and can offer both increased release and adhesion solutions. With multiple meatcling and easy-peel levels combined with numerous converting services and techniques, we have a solution ready to fit any customer’s process.

Regular

Regular is the standard for fibrous and has no interior impregnation in the casing. This is typically used for applications where special treatments such as meat-cling and easy-peel aren’t required.

MeatCling

MeatCling is used for the production of cooked, smoked and dried sausages, where controlled meat adhesion is required to ensure that the casing adheres to the sausage surface in a predictable and controlled manner during the ripening and curing cycles.

The MeatCling fibrous casing offers excellent adhesion, permeability and peelability. It’s particularly suitable for dry and semi-dry products such as salami-type sausages. You can choose a meat-cling level that suits your production requirements. For example, the lower level is used for dipped and coated salamis where casing is peeled off before further processing. A stronger meatcling solution is needed for dry sausages with longer ripening times. MeatCling guarantees the consistency of adhesion along the entire surface of the sausage. Since the casing faithfully adheres to the sausage, highend- product quality and an attractive appearance are also ensured.

A high meat-cling casing needs to be peeled off properly, therefore, STS MeatCling also offers the best peelability, which ensures easy handling for the meat-product manufacturers, retailers and consumers alike. STS can offer a range of meat-cling levels ranging from MeatCling Ultra (MCU) and High (MCH) to Low (MCL) and Extra (MCE). MeatCling is available in all standard shapes and sizes as well as in a range of attractive colors. The casings can also be supplied with up to six-color prints.

EasyPeel

EasyPeel is a special treatment on the inner surface that helps the peeling process. It’s ideal for cooked and smoked meat products, hams and emulsion-type sausages where easy peeling properties are needed. EasyPeel is also very useful if the product is tempered and the casing is peeled off prior to slicing.

EasyPeel casings offer excellent stretchability and permeability for high and predictable end-product quality. No matter whether you’re processing dry hams, smoked meats, cured meats and similar products, you can always rely on EasyPeel’s first-class peeling and handling properties. By finding the optimal balance between peelability and adhesion, it’s possible to speed up the

sausage production process and improve the efficiency of the operations. Less manual labor is required for peeling, and if the casing is peeled off by the end user, the easy and effortless release of casing contributes to consumer preference and satisfaction.

EasyPeel is available in all standard shapes and sizes as well as in a range of attractive colors. It can be tailored from low to extra-high EasyPeel (EPZip>EPL>EPH>EPE>EPIT). It can be delivered shirred, clipped or tied to length, as reel-stock and supplied with up to six-color prints.

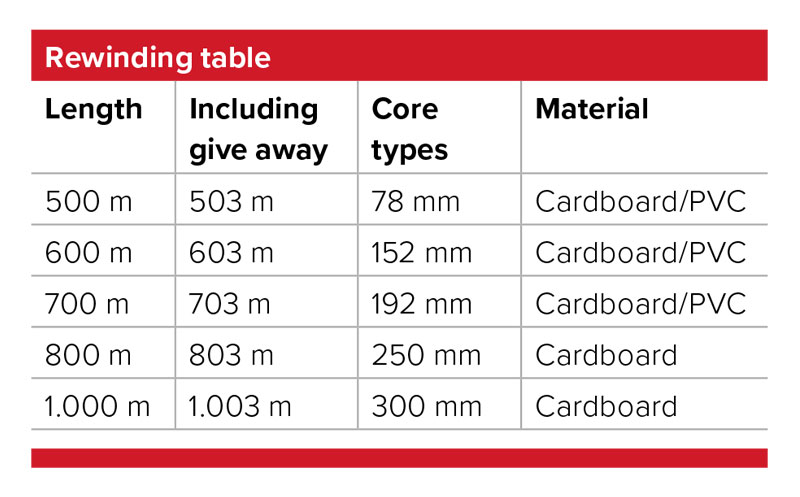

Rewinding and bundling

We can offer rewinding and bundling in various lengths and for different reel sizes. This can be done in combination with printing, pre-sticking, coating or multiple combinations. Bundling is the same as rewinding, but there is no core.

Tying

For manual operations, we can supply casings as pretied pieces. We have special capability for long lengths and large codes. We use two types of tying strings: three-thread polyester and five-thread polypropylene.

Drilling

Drilling is an option for pre-tied and clipped casing pieces. By puncturing small holes at the tied end of the casing, it’s possible to prevent air and moisture from being trapped at the top of the final product. This guarantees a high-quality end result.

Smoke

STS Smoke is a RTU fibrous casing with a smoke color and favor. It features a liquid smoke coating that eliminates the need to use smoke generators or liquid smoke. The coating imparts a natural smoke aroma and color, giving your meat or poultry product a smoky favor and appearance. By reducing or eliminating the time required to smoke your food products, you can improve yield, productivity and profitability.

Consistent flavor diffusion and even coloration are additional benefit of fibrous casings with built-in smoke. There is no fluctuation in smoke aroma or intensity, and unlike a traditional smoking process, no rack marks are left on the surface of the product. This results in an end product that isn’t only delicious in terms of taste but also exquisite in appearance. Liquid smoke also has the benefit of reducing environmental loads with zero smoke gas emissions into the atmosphere.

The smoke concentration can also be adjusted to fit applications that require only a light color and smoke aroma to heavier applications that require an intensive smoke aroma and color.

Netting

The Net family features the perfect combination of fibrous casings and a net to give you an appealing “specialty product” appearance, high mechanical strength and stable caliber. The level of adhesion and peelability can be precisely modified to meet your requirements.

The eye-catching net shapes give your sausages the pleasing look and feel of a hand-made product. To the discerning consumer, this traditional look implies premium quality and delicious flavor. We have a wide range of non-elastic or semi-elastic nets with cell shapes varying from popular honeycomb to geometric patterns such as rectangular or square shapes, some of which are registered. The net forms an integral part of the casing and adds value to your product through its unique visual appearance. The casing is easy to handle and stuff as long as you follow the guide in the “Netting” section.

Cutting

Cutting is possible with or without printing, pre-sticking or a combination. In most sizes, we can slit casing tubing open along one side or two sides and cut it to sheets up to 140 centimeters long.

Cutting options

Normally all sizes cut to lengths up to 140 cm. All sizes slit open on one side and cut to lengths up to 140 cm.