Cellulose Casing

The right casing for any application.

STS-Pak is a big volume product, but it is not a standard solution. STS-Pak is always tailored to fit each customer’s process and application requirements. After making the choice between Rapid Peel and Printed casings, the casing can be tailored in multiple combinations both for increased efficiency and added appeal.

History has proven that we have something to offer all types of cellulose casing

customers and we will support you in developing the most optimal solution for you.

Product options.

Printed Casing.

We can offer you one-color printing on one or both sides. Print your company logo or the list of ingredients and use STS-Pak as the final packaging. You never have to compromise profitability for the benefit of a great look, and as ever it is ready to use straight out of the box.

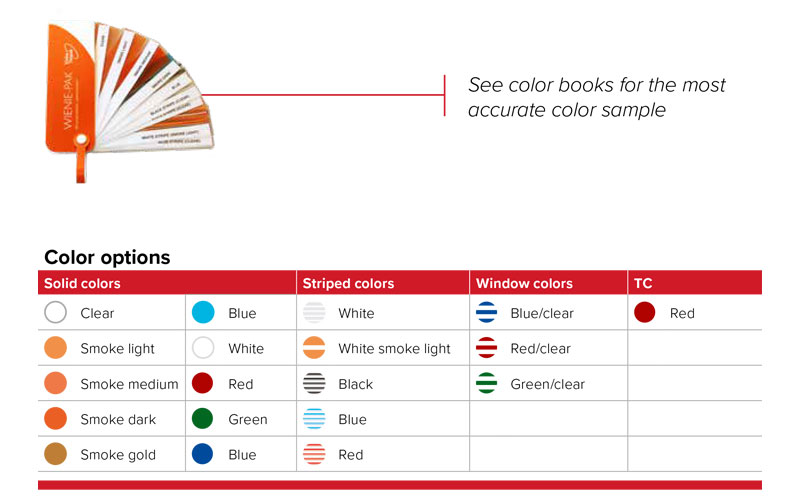

Color options.

STS-Pak offers two options from which to choose. STS-Pak casings can be delivered with stripes or in solid colors.

Solid-Color Casings

Solid-color STS-Pak casings are widely used in the industry. The pigments used are integrated in the casing structure for safety. Here are the main reasons to use solid-color casings:

Peeling control: In addition to the control options that stripe casings can provide, a solid blue colored casing provides 100% coverage of the sausage surface. Thus, any risk of small pieces of the casing remaining on the final sausage can be prevented.

Appetizing look: When the sausages are sold with the casing on, a smoke color can provide a more appetizing look. Often, these colors are combined with printing for a very appealing product and brand strengthening.

Colored stripes

The STS-Pak stripes are manufactured using patented technology. The stripes are embedded in the casing structure during extrusion. This guarantees that there is no risk of contamination of the sausages. There are two main reasons why stripes are selected:

Product identification: Often, multiple types and qualities of sausages are manufactured in the same production line. Stripes provide an excellent way of identifying the production. This is achieved through a wide range of possibilities provided by a combination of different colors and amount of stripes on the casing. We offer 6 different colors and 1 to 6 stripes on the casing circumference.

Peeling control: To minimize the risk of small pieces of casing remaining on the sausages after peeling, a contrasting stripe color can be used for easy detection after peeling. This can provide an extra guarantee against contamination of the final sausage with fragments of casing.

End-Closure Types

STS-Pak strands can be delivered with OE (open end) or CE (close end). Strands with OE are manufactured for use in manual stuffing operations. Strands with CE are especially designed for use on high-speed stuffing equipment. Wienie-Pak can therefore be tailored to meet the demands of both big and small companies and for precise, fast production processes.

Open-end

STS-Pak Open End casings are mostly used in butcher shops, with manual stuffing equipment. The use of these types of casings is very similar to the use of a natural casing.

Standard (CE)

This is the most versatile type of end closure for a wide variety of automated stuffing equipment. The CE type is unique in the industry because it is a solid and reliable closure that contains a vent hole. This allows for very fast entrance of the stuffing tube in the strand without any risk of premature release of the closure.

Push Pak (CE-PP)

The Push Pak closure is most often used in stuffing applications where there is a risk that the meat emulsion might leak through the vent hole of the CE closure. This can occur in circumstances where a liquid meat emulsion is used. It is mainly used on stuffing machines with brake.

Knotted (CE-KN)

The Knotted Closure provides the most complete and ultimate closure on the market. It is suited for all types of stuffing machines. With this closure, there is virtually no casing/product loss at the beginning of the strand during stuffing. It also provides the possibility for a first usable link.